In the world of pressure canning, it’s important to understand the difference between a weighted gauge and a dial gauge pressure canner. While both are designed to safely can your favorite foods, they operate in slightly different ways. A weighted gauge canner uses a weighted valve system to regulate pressure, providing a reliable and foolproof method. On the other hand, a dial gauge canner features a pressure gauge that allows you to closely monitor the pressure inside the canner. Whether you’re a beginner or a seasoned canner, knowing the difference between these two options can help you choose the right tool for your canning adventures.

What’s The Difference Between A Weighted Gauge And A Dial Gauge Pressure Canner?

Pressure canning is an essential method of food preservation that allows you to safely store perishable goods for long periods. Whether you are a seasoned canner or just starting out, understanding the difference between a weighted gauge and a dial gauge pressure canner is crucial in making informed choices and ensuring the safety of your canning process. In this comprehensive article, we will explore the mechanisms, advantages, disadvantages, and key differences between these two types of pressure canners, as well as factors to consider when choosing the right canner for your needs.

Overview of Pressure Canning

Before delving into the specifics of weighted gauge and dial gauge pressure canners, it is important to have a general understanding of pressure canning, its significance, and safety considerations.

What is Pressure Canning?

Pressure canning is a food preservation method that uses high pressure to create a sealed environment inside canning jars, effectively killing microorganisms and enzymes that may cause spoilage. By subjecting the jars to temperatures higher than boiling point, pressure canning ensures the destruction of harmful bacteria like Clostridium botulinum, all while extending the shelf life of canned goods.

Why is it Important?

Pressure canning is crucial for preserving low-acid foods, such as vegetables, meats, and poultry, as these have a higher risk of containing the harmful bacterium Clostridium botulinum. This bacteria thrives in the absence of oxygen and can cause botulism, a potentially life-threatening illness. Utilizing a pressure canner is the only safe way to eliminate C. botulinum spores, reducing the risk of food poisoning and ensuring the long-term safety of your canned goods.

Safety Considerations

When undertaking pressure canning, it is essential to prioritize safety. This includes following proper canning procedures, using tested recipes from reliable sources, and carefully selecting the appropriate equipment. Both weighted gauge and dial gauge pressure canners have safety features in place; however, understanding their mechanisms, advantages, and disadvantages will greatly contribute to the overall safety of your pressure canning process.

Weighted Gauge Pressure Canner

A weighted gauge pressure canner is a traditional type of pressure canner that utilizes a weighted pressure regulator to control the pressure inside the canner. This type of canner is often considered easier to use, making it a popular choice among home canners.

Mechanism and Operation

In a weighted gauge pressure canner, the weighted pressure regulator is placed on top of the vent pipe. As the pressure builds inside the canner, steam escapes through the vent pipe until it reaches the desired pressure. At that point, the weighted pressure regulator starts to rock gently, releasing small bursts of steam to maintain a consistent pressure level.

Advantages

One of the significant advantages of a weighted gauge pressure canner is its simplicity. The rocking motion of the weighted pressure regulator provides an audible and visual indication of the pressure level, making it easy for canners to monitor the canning process without relying on additional instruments. This simplicity also translates to ease of use, especially for beginners or those who prefer a straightforward canning experience.

Another advantage is that weighted gauge pressure canners are considered more forgiving in terms of altitude adjustment. The weight of the pressure regulator compensates for altitude differences automatically, reducing the need for manual adjustments.

Disadvantages

While weighted gauge pressure canners offer simplicity and ease of use, they may have slightly less precise pressure control compared to dial gauge pressure canners. The rocking motion indicates pressure within a range rather than a specific value, limiting the ability to fine-tune the pressure precisely.

Dial Gauge Pressure Canner

A dial gauge pressure canner, also known as a pressure canner with a pressure gauge, features a dial gauge that provides a numeric reading of the internal pressure. This type of pressure canner is commonly used by more experienced canners who prefer precise pressure control.

Mechanism and Operation

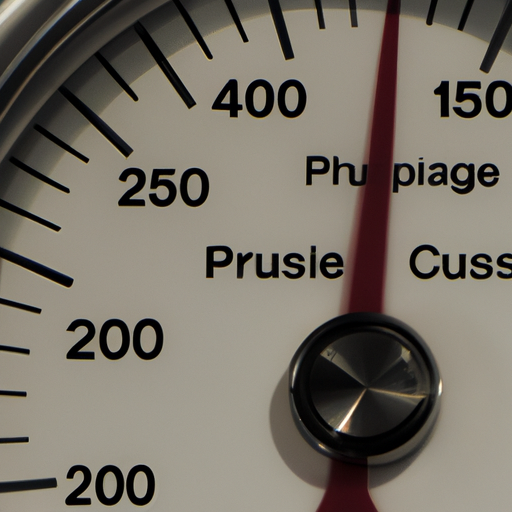

A dial gauge pressure canner is equipped with a pressure gauge that shows the exact pressure inside the canner. The dial gauge measures the pressure using a spring mechanism, which moves a needle along a calibrated scale corresponding to the pressure level. By carefully monitoring the dial gauge, canners can ensure that the pressure stays within the desired range.

Advantages

The main advantage of a dial gauge pressure canner is its precise pressure control. The numeric reading allows for accurate adjustments to the pressure level, ensuring consistent and safe canning results. This level of precision is especially valuable for recipes that require exact pressure specifications, where a small deviation can affect the safety and quality of the canned product.

Disadvantages

While offering accurate pressure control, dial gauge pressure canners require additional attention and monitoring. The canner must be checked regularly during the canning process to ensure that the pressure remains within the safe range. This monitoring helps catch any fluctuations or deviations that could compromise the safety and quality of the canned goods.

Key Differences between Weighted Gauge and Dial Gauge Pressure Canners

The primary difference between weighted gauge and dial gauge pressure canners lies in their pressure-regulating mechanisms. A weighted gauge canner uses a weighted pressure regulator that rocks to maintain pressure within a range, while a dial gauge canner utilizes a numeric pressure gauge for precise pressure control. This distinction affects the ease of use and the level of control provided to the canner. While a weighted gauge canner offers simplicity and ease of use, a dial gauge canner provides greater precision but requires more attention and monitoring from the user.

Accuracy and Precision

Accurate pressure measurement is crucial in pressure canning to ensure the safety and quality of canned goods. Understanding how the gauges measure pressure, their calibration, and the effects on canning times is essential for successful results.

How the Gauges Measure Pressure

In a weighted gauge canner, the pressure is indicated through the rocking motion of the weighted pressure regulator, providing a visual and audible indication within a specific range. On the other hand, a dial gauge canner measures the pressure using a spring mechanism, displaying a numeric reading on the dial gauge for precise pressure control.

Reading and Calibration

Reading the pressure on a weighted gauge canner is relatively straightforward since the rocking motion indicates the pressure within a predetermined range. However, dial gauge canners require careful reading and calibration. The dial gauge should be checked for accuracy before each canning season, ensuring it is properly calibrated and displaying the correct pressure reading.

Effects on Canning Times

The accuracy and precision of the pressure control mechanism directly affect the canning times required for different foods. While both weighted gauge and dial gauge canners can achieve the necessary pressure to kill harmful bacteria, the precision of a dial gauge canner may allow for more accurate timing adjustments, resulting in optimal canning times for specific recipes.

Safety Considerations

Regardless of the type of pressure canner you choose, safety remains the top priority. Adhering to tested recipes from reliable sources, following proper canning procedures, and being aware of the altitude adjustment requirements are essential for ensuring safe pressure canning. Additionally, regular maintenance and calibration of the pressure canner’s gauges, particularly for dial gauge canners, contribute to the accuracy and safety of the canning process.

Ease of Use

The ease of use of a pressure canner greatly impacts the overall canning experience. Factors such as operating instructions, pressure monitoring, adjustments, and maintenance should be considered when determining which type of pressure canner suits your needs.

Operating Instructions

Both weighted gauge and dial gauge pressure canners come with detailed operating instructions. However, beginners or those seeking a simpler canning experience may find weighted gauge canners more user-friendly due to their straightforward mechanism and the audible and visual cues provided by the rocking motion of the weighted pressure regulator.

Monitoring Pressure

Pressure monitoring is an integral part of pressure canning. While a weighted gauge canner provides a visible rocking motion to indicate pressure, a dial gauge canner requires more proactive monitoring. Canners using a dial gauge should regularly check and adjust the heat source to maintain the desired pressure, ensuring safe and consistent canning results.

Adjustments and Maintenance

Weighted gauge canners typically require less adjustment and maintenance compared to dial gauge canners. The weighted pressure regulator compensates for altitude differences automatically, reducing the need for manual adjustments. Dial gauge canners, on the other hand, may need periodic calibration to ensure the accuracy of the pressure readings. Proper care and maintenance, including routine cleaning and inspection, are necessary for both types of pressure canners to ensure their longevity and performance.

Availability and Cost

Availability and cost factors play an important role in choosing the right pressure canner for your needs. Understanding the market variability and various price points allows you to make an informed decision while considering your budget.

Market Variability

The market offers a wide range of pressure canners, including both weighted gauge and dial gauge models, each with its own set of features and price points. Availability may vary depending on your location and the specific brands and models offered in your region. Researching local distributors, online marketplaces, and community networks can help you identify the most suitable options for your location.

Price Points

The price of a pressure canner can vary depending on factors such as size, materials, brand, and additional features. Generally, weighted gauge canners tend to be more affordable compared to dial gauge canners. However, it is important to consider the long-term value and durability of the canner, as well as the overall benefits it provides in terms of safety and ease of use. Budget-conscious canners can often find high-quality models that meet their needs without compromising safety.

Compatibility and Accessibility

Ensuring compatibility with your stove type and considering geographical factors are important when selecting a pressure canner.

Suitable Stove Types

Most pressure canners are designed to be used on standard home stovetops, whether gas or electric. However, it is crucial to check the compatibility of the canner with your specific stove type. Some canners may not work with induction cooktops or certain non-standard heat sources. Verifying compatibility before making a purchase will help avoid any potential issues and ensure a seamless canning experience.

Geographical Considerations

Geographical factors, particularly altitude, can impact pressure canning. As altitude affects the boiling point of water, the pressure required for safe canning may vary at different elevations. Weighted gauge canners are generally more forgiving in terms of altitude adjustments, making them suitable for canners living at various elevations. Dial gauge canners, however, may require manual adjustments to compensate for altitude differences. Consulting altitude charts or contacting your local Cooperative Extension office can provide guidance on the adjustments needed for safe pressure canning in your area.

Choosing the Right Canner for Your Needs

Selecting the right pressure canner involves considering a variety of factors, including personal preferences, budget, and specific canning requirements.

Factors to Consider

When choosing between a weighted gauge and a dial gauge pressure canner, it is important to assess your personal preferences and canning goals. Consider factors such as your experience level, desire for precise pressure control, and willingness to closely monitor the canning process. Evaluating the recipes you plan to can and their pressure requirements will also help guide your decision-making process.

Personal Preferences

Your personal preferences play a significant role in determining the most suitable canner for you. If you prefer a simpler and more intuitive canning experience, a weighted gauge canner may be the ideal choice. On the other hand, if you value precise pressure control and are willing to invest more attention and monitoring into your canning process, a dial gauge canner may be the better option.

Budget

Your budget is an important consideration when purchasing a pressure canner. While dial gauge canners generally offer more precise pressure control, they also tend to be pricier compared to weighted gauge canners. It is essential to strike a balance between your budget and the features that are most important to you. Researching different brands, models, and price ranges can help you identify high-quality canners that meet your needs while staying within your budget.

In conclusion, understanding the difference between a weighted gauge and a dial gauge pressure canner is key to successful and safe pressure canning. Both types of canners have their advantages and disadvantages, offering varying levels of simplicity, precision, and control. By considering factors such as accuracy, ease of use, availability, compatibility, and personal preferences, you can make an informed decision and choose the right pressure canner for your canning needs. Remember, prioritizing safety, following tested recipes, and maintaining your chosen canner will ensure the long-term preservation of your delicious canned creations. Happy canning!